I. Machine model:ZH-GD1200SL fully-automatic folder gluer (4&6 corner)

Mainly suitable for corrugated box folder gluing

II. Features:

● The whole machine adopts the structure of laser-cut steel plates.

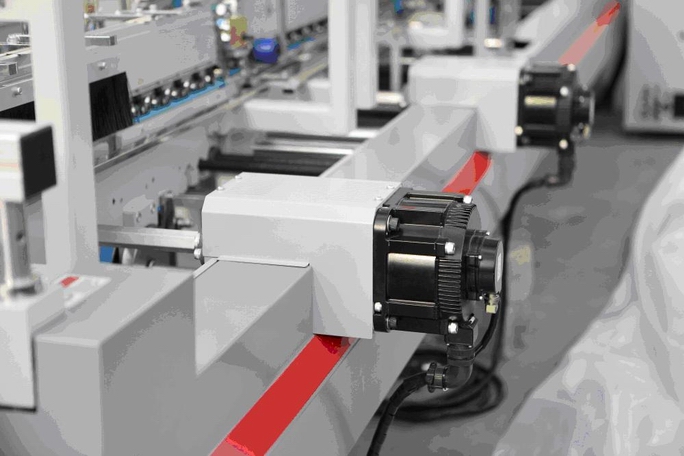

● Use German Contitech synchronous belts and wheels, correct running ratio, high speed, stable working, low noise and long service life.

●Modular structure and hommization design can enhance the installation and box change-over time.

●Inner couriers in the machine are adjusted by motors (position indicator is optional)

●Bearings are used in this machines: NSK, ASHAHI, HRB. Most of electrical components are Schneider brand.

Some advantages:

1. Belts are running in rail guide, will not go to sides.

2. Heavy-duty pneumatic longer conveyor, suitable for corrugated, and the whole conveyor can be moved left and right. The two sections of the conveyor can be moved front and back, up and down, more suitable for different corrugated boxes.

3. Equipped with jogger, avoiding fish-tail boxes.

4. The whole machine is of more compact structure, more beautiful figure.

5. Fastening devices for shafts are used to make the machine run more stable and longer service life.

6. The speed in pressing section is 30% faster than that in the main section, avoiding the boxes jammed onto the conveyor.

![]()

III. Main Technical Parameter:

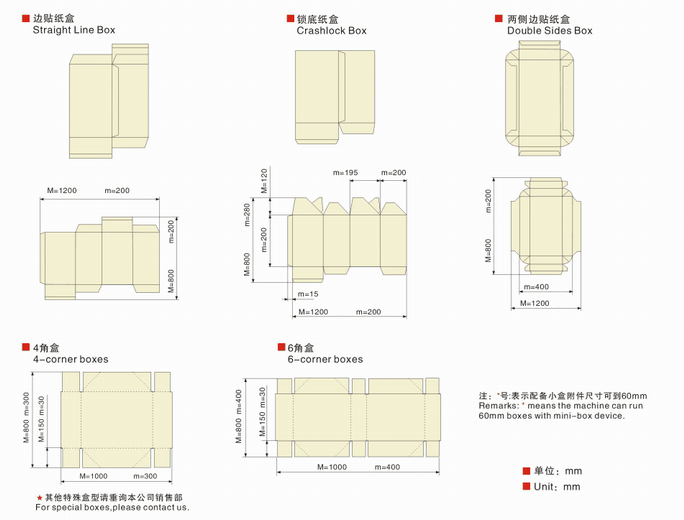

Paper size:

Max size for straight line box:W×L: 1200×800 mm Min:90×60 mm

Max size for double-sided box:W×L: 1100×800 mm Min:90×60 mm

Max size for lock bottom box:W×L: 1100×800 mm Min:120×60 mm

Max size for 4-corner box:1100 mm Min:150 mm

Max size for 6-corner box: 1100 mm Min:250 mm

Paper weight: duplex box 300-800g/m2, B、C、E、F、G (Corrugated)

Max speed: 250m/min

Overall dimension: 13800×1700×1400mm (L长×W宽×H高)

Weight: 8000Kg(around)

Power consumption: 26KW

IV.Basic configuration:

Feeder

●RAPPLON feeding belts

● Equipped with adjustable feeding knives: 2 pcs

● Equipped with vibrator motor : 1 set

● Equipped with Japanese infinite speed regulator : 1 set

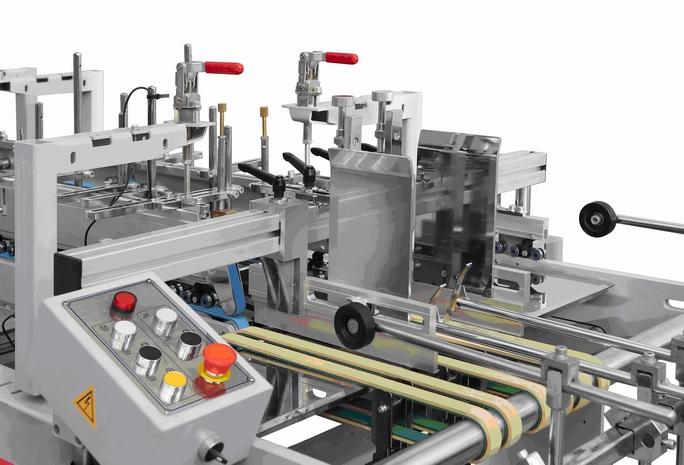

4&6Corner Section

● This section is installed in a stand, according to the folding size, set up and rotate the hook height. Japan Yaskawa servo system is used.

●Inner couriers are adjusted by motors (6 sets)

●NITTA belts: 12 pcs

Lower Gluer

● Lower gluing tank both at left and right

● Multi-layer sealing anti-leaking device is used in shaft core.

● Stainless steel gluing wheel is used.

Folding section

● Special long folding section, boxes can be well folded and formed in this section.

● Inner couriers are adjusted by motors: 2 set

● Rail-guide for belts are used to avoid belts going to sides.

● NITTA folding belts 6 pcs

Pressing section

● Taiwan Fotek sensor and counter

● Pneumatic kicker for counting

● Nitta belts

Conveyor

● Long conveyor design

● Pneumatic control

● The upper section can be moved front and back.

● The two belts are in driving system, so they could be in more synchronous running.

● Belts specification