This machine is

mainly used to coat on solvent or water-based ink and cover screen printing and

coating, like scratch card and lottery.

1、Screen printing section, main functions and configurations:

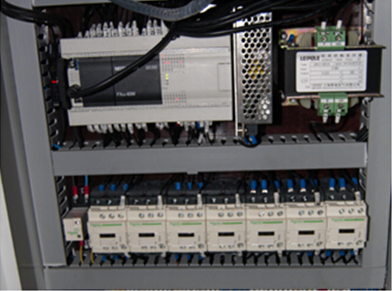

1. Frequency conversion braking is controlled by motor driver, and machine is controlled by Japan Mitsubishi PLC, and the 12 inch Eview touch screen can display all the functions and data, which makes the operating easy and convenient.

2. Inspection are through the whole printing, machine will automatically stop if any failure occurs, and deduct paper waste.

3. The perfect alarm system can remind operating persons to exclude the malfunction and enhance maintenance efficiency.

4. The whole electric part adopts imported Schneider, Mitsubishi and Omron products, which enhanced electrical system stability.

The whole electric part adopts imported Schneider

5. Machine frame and parts are machined by CNC to ensure the main parts precise and machine steady, also help machine runs fast and long.

6. printing roller adopts stainless steel 304 (1.96mm), precise and durable; the grippers’ elastic range can be designed flexibly, and can be adjusted according to paper weight, easy and convenient.

7. The pneumatic controlled delivery table can be turned by 90 degrees, which makes it convenient to clean screen. With micro adjustments you can realize all direction adjustments from up-down, front-back and left-right.

8. The integrated lubrication system: main transmission part can enlarge machine precise and service life.

9. The cover is cut by laser and cold pressing. Metal cover by CNC, and acrylic acid flat paint etc to avoid the of corrosion from printing solvent to machine.

10. The machine system adoptsTaiwanairtac pneumatic parts, screen frame and printing knife and adopts pneumatic pressure.

11. machine imported bearings are more than 98% from NTN, NSK and IKO.

12. Configuration is 4-4 suctions feeding, and makes film laminating advancing more steadily.

l printing unit technical parameters:

|

型号 技术参数 |

1020 |

|

最大纸张尺寸(mm) |

1020X740 |

|

最小纸张尺寸(mm) |

450X320 |

|

最大印刷面积(mm) |

1020X720 |

|

*纸张厚度(克/m2) |

120-350 |

|

网框尺寸(mm) |

1280X1140 |

|

*印刷速度(张/小时) |

1000—2600 |

|

总功率(kw) |

9.0 |

|

总重量 (kg) |

4500 |

|

外形尺寸(m) |

3.6×2.35×1.32 |

2、1020 paper-clip type IR automatic dryer

Brief introduction

This machine adopts paper-clip type feeding, flip-over vertical and electrical heating recycling drying section. And is widely used on ceramic flower paper, packaging printing, PET xylopyrography, hydrographics transfer printing etc. with all kinds of printing ink and pigment drying.

The machine main body is composed by 3 semi enclosed tunnel box structure heating bars and 3 open code fan section. And total 1346 pcs of paper clips.

3. Each heating bar box has 2 groups of IR heating tube on its top, a recycling fan after the hot wind box can make a hot-wind jet flow, and ensure temperature and fan amount average.

4.This machine adopts PID automatic temperature adjustments and heat preservation and insulation layer inside of heating box can enhance heat efficiency.

5. Air exhausting system on the heating tube front, can remove the pollution air occurred when drying.

6. Paper clip feeding is controlled by photoelectrical, and check the flip over movement automatically, it can change into automatic and manual mode.

7.Paper clip adopts cold drawn steel material and make a polishing & galvanization solution, which can protect the material. Also deduct paper falling.

8. Electrical parts adopts Schneider, Omron, and temperature controller is from Taiwan Qisheng, heating roller are controlled by solid-state relay.

9. Delivery part adopts 7 feeding belts, and paper-tidy structure adopts pneumatic paper tidying structure, stainless steel delivery table.

l Bellow picture is shortened GWD-1020 drying section.

Feeding bridge structure.

Whole drying tunnel

l drying init technical parameters:

|

型号 |

Model |

1020 |

|

最大输送纸张尺寸(mm) |

Max. paper size (mm) |

1020×740 |

|

最高温度(℃) |

Max. temperature |

Indoor temperature to 70℃ |

|

纸夹数(p) |

Paper clips |

1346 PCS |

|

总功率(kw) |

Total power |

42 |

|

总净重(kg) |

weight |

6200 |

|

外形尺寸(m) |

Overall dimensions |

21.1×2.35×2.8 |

Remark:

1.The drying section can be optional according to customer’s request, and all-closed structure is available.

2.Pneumatic opening gripper is optional too, to make the material can be dried recycled.

3.Paper clips standard surface is galvanization, and options can be chromeplate, stainless steel or special-angle paper clips.

3. UV curing unit

1. Feeding belt adopts Teflon glass fiber layer, which is high temperature resistant, rub resistant and radiation resistant.

2. Two sets of fan systems can ensure paper sticky to belt and will not move, meanwhile exhaust the heat.

3. Single box and single lamp can work separately; also multi boxes and multi lamps work together. As for power mode, 50%, 75% and 100% are for your choice, which can help save labor service life and save energy.

4. The belt adopts pneumatic auto correction system to avoid belts going wrong.

UV curing unit technical parameters

|

型号 |

Model |

GUV/IR-1050 |

|

最大输送宽度(mm) |

Max. feeding width (mm) |

1100 |

|

输送网带速度(m/min) |

Feeding belt speed(m/min) |

0~65 |

|

灯管功率x灯管数(kw×根) |

Lamp power*quantity(kw* pcs) |

9.6 x 3 |

|

总功率(kw) |

Total power(kw) |

38 |

|

总净重(kg) |

Total weight |

1200 |

|

外形尺寸(mm) |

Overall dimension |

3600×1815×1225 |