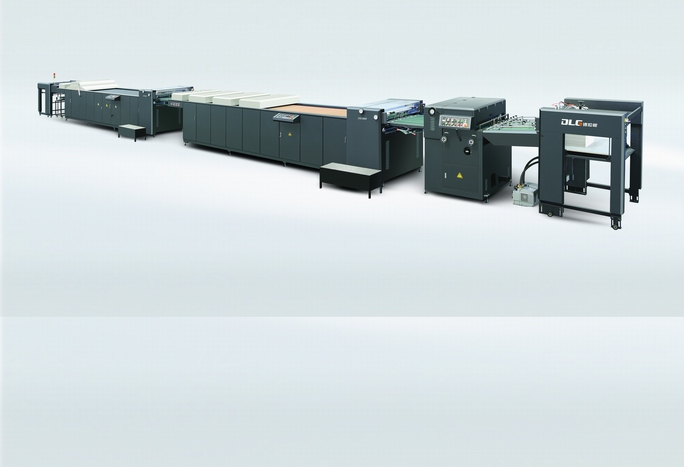

Performance And Characteristics:

1. Automatic feeding section

High-speed stable feeder free from maintenance.

Options: movable guide rail, manual feeding table for paper

size feeder could not handle.

2. Powder-removing section

Adopt flannel roller and heating roller double way to clean

the powder on paper surface and increase the coating effects,

convenient adjustment and operation.

3. Grounding coating / IR drying section

This section is used for water-based varnish before UV coating

to

fill with small holes on paper surface to save UV varnish.

4. Infrared hot air drying / cooling fan

Ministry

The unique design of hot-wind drying make water-based

coating drying

faster and more purely.

5. UV coating / UV curing section

Adopt reverse roller and speed regulating to control varnish

thickness, automatic stop for paper jam to reduce sheets to be

wasted.

6. UV curing

This section is composed of lamps, reflectors, air cooling

and exhausting systems. Sheets coated by UV varnish will

be dried here.

7. Automatic delivery section

Jogging times can be set according to paper weight. Pneumatic

joggers keep sheets delivered orderly. Equip with counter for

coated sheets, pre-delivery table which will be automatically

open when paper jam in delivery.

8. Machine PLC control, man-machine

dialogue.

● Air knife system for

light paper more than 80gsm is optional.